GLASS FABRICATION SERVICES

We get the most challenging projects done!

Our capabilities span the range from traditional techniques to more unconventional methods. Glassblowing, casting, fusing, and slumping are some of the traditional glass fabrication services frequently used for creating many glass products. When common methods are not applicable and innovation is required, we pride ourselves on developing new fabrication processes in house. Our projects frequently involve not only producing glass components, but also creating specialized equipment to produce them. Like developing a process for vacuum-forming sheet glass or building custom equipment for lapping glass prisms, we embrace the challenge of taking on projects others have turned away from.

Our glass-working capabilities include:

Glassblowing

Hot Casting

Kiln Casting

Fusing

Custom Glass Bending

Pressing

Glass Machining

We also have facilities for:

CNC machining

welding

Wood working

Equipment design and fabrication

tooling design and fabrication

Mold Making

Contact us today to get started on glass fabrication services.

Hot work

Hot work is a forming process in which we work directly with molten glass. For instance, glassblowing, ladle casting, solid working, pressing, etc. Glassblowing is a core Keer capability. Our craftsman have trained with Italian master glass blowers and have extensive experience working with artists and industry professionals.

Finishing dished shade for LA Central library restoration

Mold blowing components for Bloomberg sculpture

Ladling glass from furnace

Sand casting glass disk

Kiln work: casting, Fusing, bending

From traditional oven-work (casting, Pâte de verre, sagging bending, etc.) to innovative, cutting edge techniques such as high-temperature vacuum forming, we know the right process for your project.

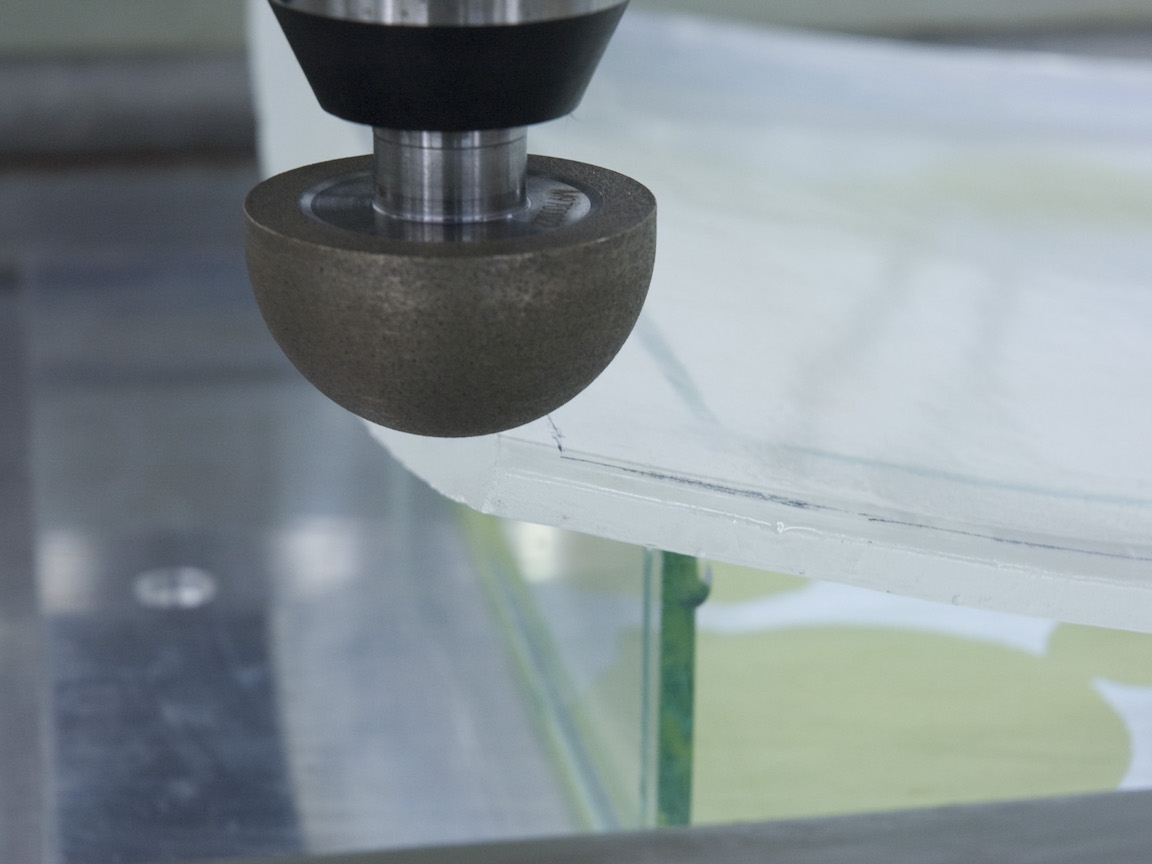

glass machining

CNC machining with diamond tools is an efficient way to create precise glass components.

Equipment design and fabrication

At Keer we don't only work with glass we also make glass-working equipment.

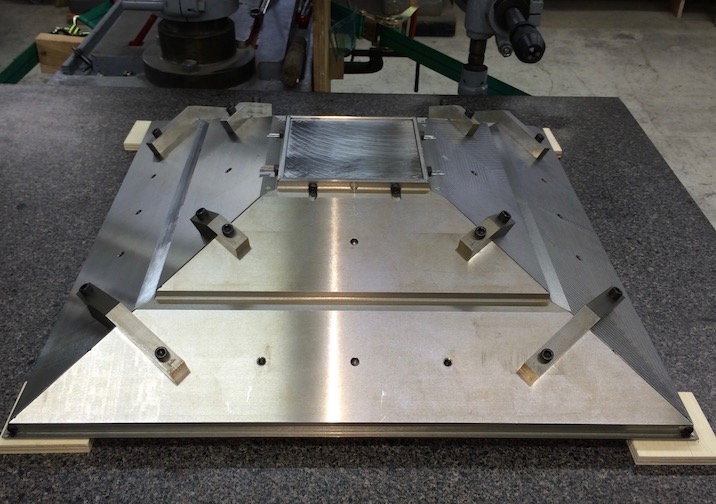

Semi-automated programmable lapping station

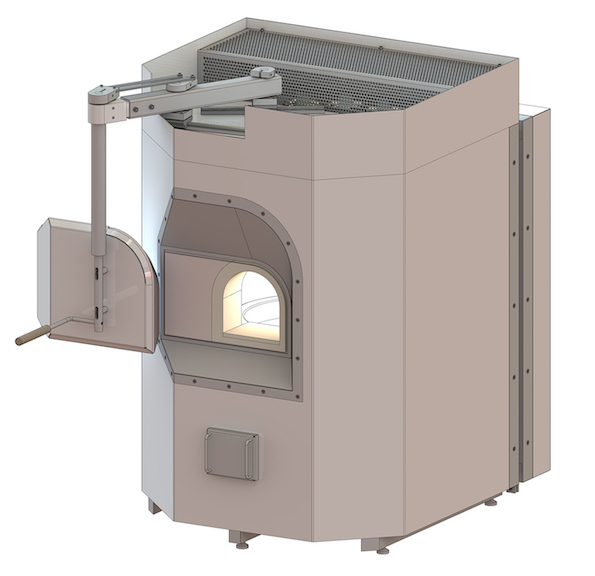

Electric free-standing crucible furnace design

Furnace cross-section

Front-load and top-load kiln design and fabrication

Custom Glassblowing Equipment Design and Fabrication

During the blowing process glass which has been gathered from the furnace cools down and periodically needs to be reheated. This is a small glory hole used for reheating glass when it gets too cold to manipulate.